We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Divimax, the container loading divider by JAC

-Divides the effort

-Produces a maximum number of containers

-In a minimum of space

-Provides ergonomics on a physically demanding workstation

-Groups and folds up to 7 dough pieces of 1580 g directly ontothe output conveyor

-Calibrates containers from 2 kg to 11 kg

-Produces up to 327 containers/hour

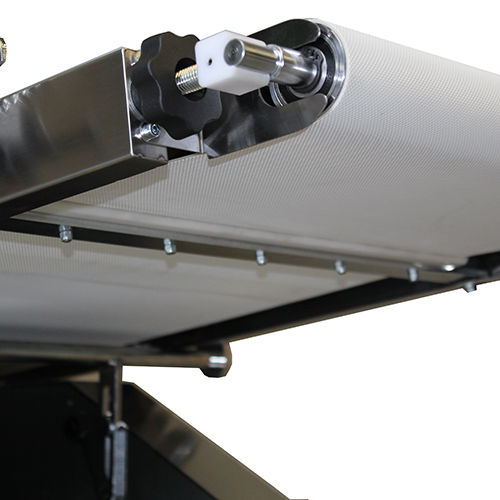

The belt is kept clean throughout use.

Reduces oil consumption. Fitted with a filter and a low level alert.

Adjusts the weight quickly and accurately

Prevents the dough pieces from sticking to the belt.

The belt is kept clean throughout use.

Reduces oil consumption. Fitted with a filter and a low level alert.

Adjusts the weight quickly and accurately

Prevents the dough pieces from sticking to the belt.

|

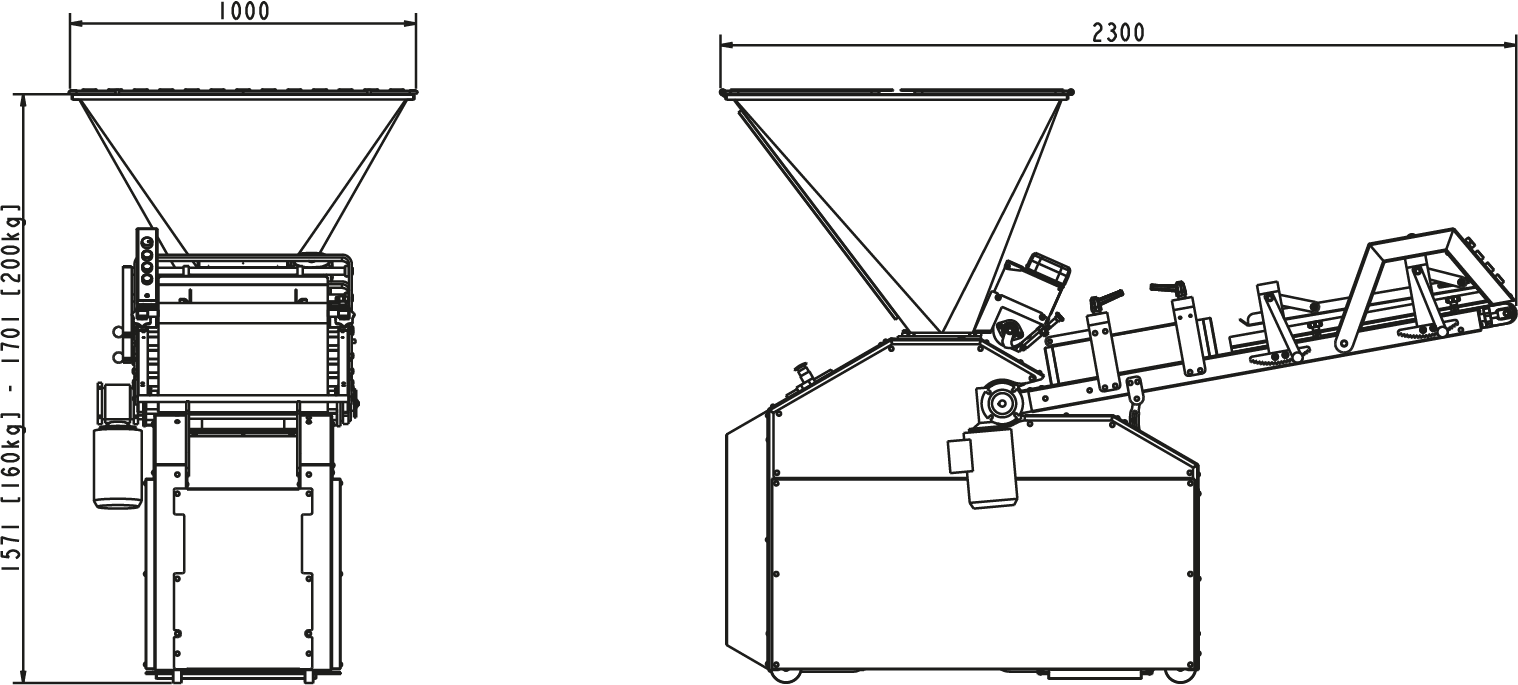

Minimum/maximum container weight in kg |

2/11 |

|

Maximum capacity in containers/hour |

327 |

|

Number of dough pieces/hour in single dough mode |

1200 |

|

Weight of dough pieces in single-piece mode in g |

200 |

|

Minimum/maximum dough hydration rate |

60/75 |

|

Motor power in kW |

2,2 |

|

Power supply type in V |

400 three-phase |

|

Weight in kg |

530 |

|

Footprint in m2 |

2,3 |

|

Manual weight adjustment |

• |

|

Stainless steel body |

• |

|

Stainless steel drum |

• |

|

CONTAINER WEIGHT IN KG |

NUMBER OF DOUGH PIECES/CONTAINER |

CAPACITY/H |

DIVISION TIME OF A 160KG HOPPER IN MIN |

DIVISION TIME OF A 200KG HOPPER IN MIN |

|

2 |

2 |

327 |

14 |

17’30 |

|

3,5 |

3 |

240 |

12 |

15 |

|

7 |

5 |

156 |

9 |

11’25 |

SHARE