We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

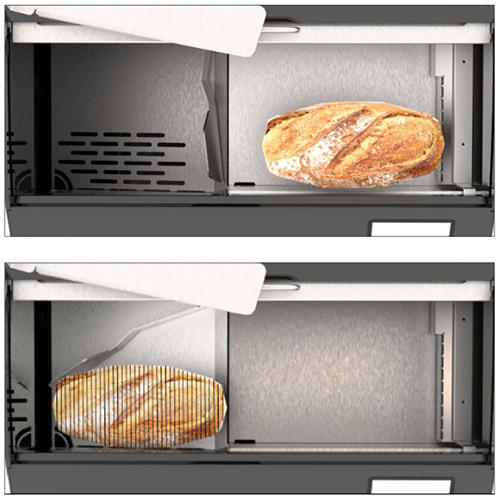

A revolution has been gradually taking off in the bakery trade in recent years: Offering the customer the ability to adapt slicing thickness to suit different types of loaf. A dense rye loaf does not need the same slicing thickness as a very holey pain de campagne.

The Varia, the variable slice thickness slicer, enables you to stand out and promote loyalty in your customers by offering them a choice of slice thickness. An extra service compared to your competitors.

If the ETL Listed mark has a "US" to the bottom right, it has passed U.S. product safety standards. If it has a "C" to the bottom left, it has passed Canadian product safety standards. If the ETL mark displays both identifiers, it meets both standards.

The ETL Sanitation mark is awarded to food service equipment that has been rigorously tested against national sanitation requirements. This mark ensures you that the equipment is fit for use during food production as the manufacturer has not only passed the initial testing, but remains in compliance by completing periodic follow-up inspections. If the ETL Listed mark has a "US" to the bottom right, it has passed U.S. product safety standards. If it has a "C" to the bottom left, it has passed Canadian product safety standards. If the ETL mark displays both identifiers, it meets both standards.

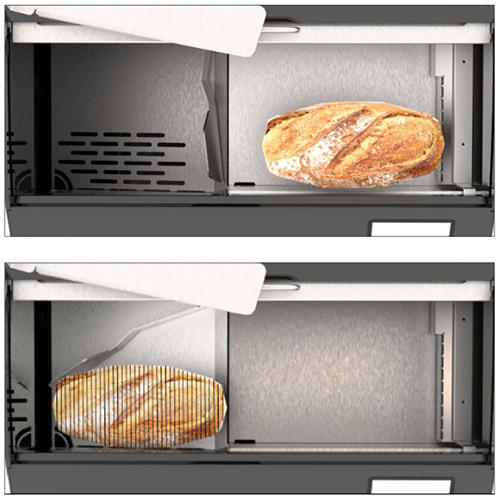

Developed to cut through a large variety of breads; from soft to dense, with a hard crust, and even sticky breads.

In order to reach the fastest possible speed for each bread type.

Fluid blade movement, avoids back-and-forth shakes. Robust solution for long-term mechanical reliability.

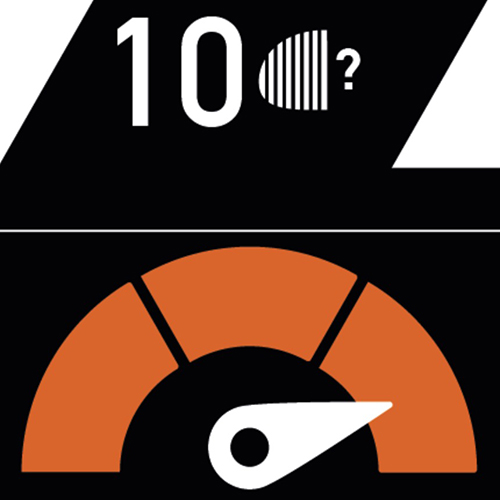

Clear and simple interface, for an immediate and intuitive use.

Clear and simple interface, for immediate and intuitive use. Only available with touch interface choice.

Minimized last slice width.

For all kinds of breads, including sharp ends. Allows to minimize last slice width.

Lights insertion zone then exit zone.

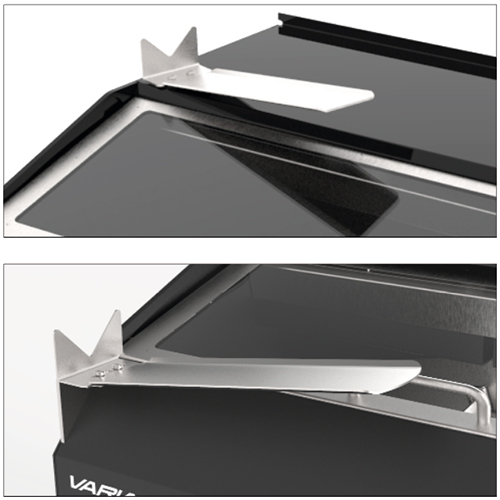

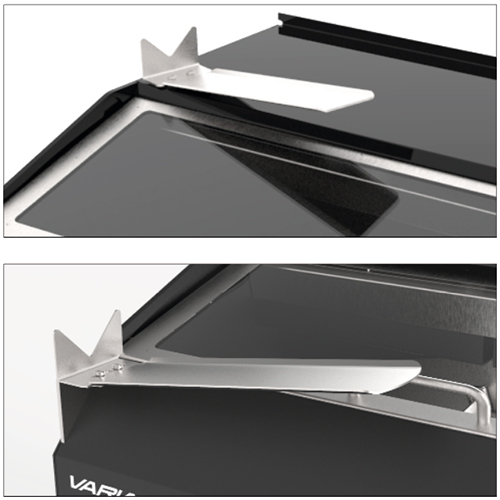

Rotating spade, above cutting chamber, to optimize ergonomics and hygiene. Two standard (left and right) bagging spade positions. Or non-rotating front position (option).

Prevents objects placed on the machine (e.g. bags) to be pushed inadvertently behind the machine when opening the front cover. Rotates for easy cleaning.

Accessible from the front of the machine, but not visible; avoids operations by a non-authorized person.

Highest safety standards, for machine use by consumers and staff. The blade cannot run when the machine is not 100% locked.

Users cannot inadvertently pinch their fingers in the front cover sliders.

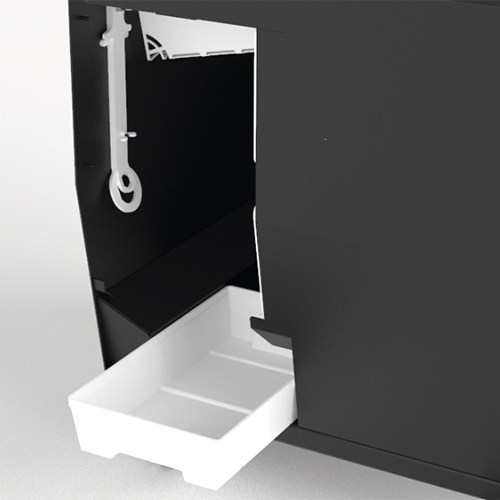

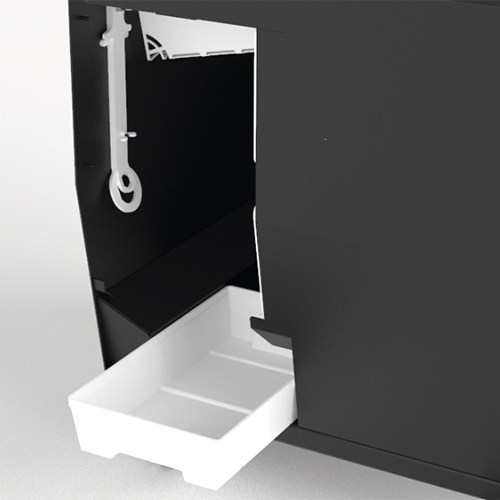

Internal architecture designed to channel bread crumbs to an easily accessible crumb tray. Flat surfaces (without recess around).

100% BPA-free satin paint (Bisphenol A): safer for you, gentler on the planet. Its low-temperature curing process significantly reduces energy consumption. Available in three solid colours: white, black or grey.

If the ETL Listed mark has a "US" to the bottom right, it has passed U.S. product safety standards. If it has a "C" to the bottom left, it has passed Canadian product safety standards. If the ETL mark displays both identifiers, it meets both standards.

The ETL Sanitation mark is awarded to food service equipment that has been rigorously tested against national sanitation requirements. This mark ensures you that the equipment is fit for use during food production as the manufacturer has not only passed the initial testing, but remains in compliance by completing periodic follow-up inspections. If the ETL Listed mark has a "US" to the bottom right, it has passed U.S. product safety standards. If it has a "C" to the bottom left, it has passed Canadian product safety standards. If the ETL mark displays both identifiers, it meets both standards.

Developed to cut through a large variety of breads; from soft to dense, with a hard crust, and even sticky breads.

In order to reach the fastest possible speed for each bread type.

Fluid blade movement, avoids back-and-forth shakes. Robust solution for long-term mechanical reliability.

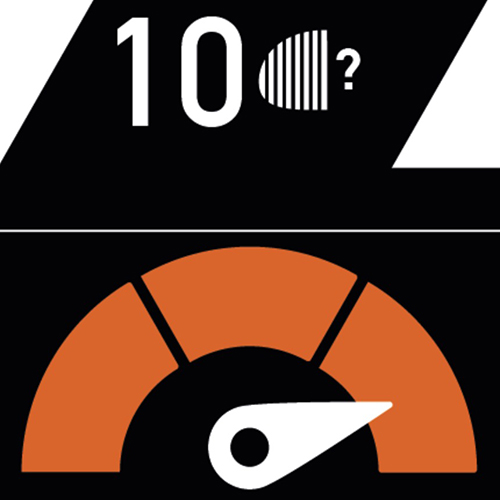

Clear and simple interface, for an immediate and intuitive use.

Clear and simple interface, for immediate and intuitive use. Only available with touch interface choice.

Minimized last slice width.

For all kinds of breads, including sharp ends. Allows to minimize last slice width.

Lights insertion zone then exit zone.

Rotating spade, above cutting chamber, to optimize ergonomics and hygiene. Two standard (left and right) bagging spade positions. Or non-rotating front position (option).

Prevents objects placed on the machine (e.g. bags) to be pushed inadvertently behind the machine when opening the front cover. Rotates for easy cleaning.

Accessible from the front of the machine, but not visible; avoids operations by a non-authorized person.

Highest safety standards, for machine use by consumers and staff. The blade cannot run when the machine is not 100% locked.

Users cannot inadvertently pinch their fingers in the front cover sliders.

Internal architecture designed to channel bread crumbs to an easily accessible crumb tray. Flat surfaces (without recess around).

100% BPA-free satin paint (Bisphenol A): safer for you, gentler on the planet. Its low-temperature curing process significantly reduces energy consumption. Available in three solid colours: white, black or grey.

|

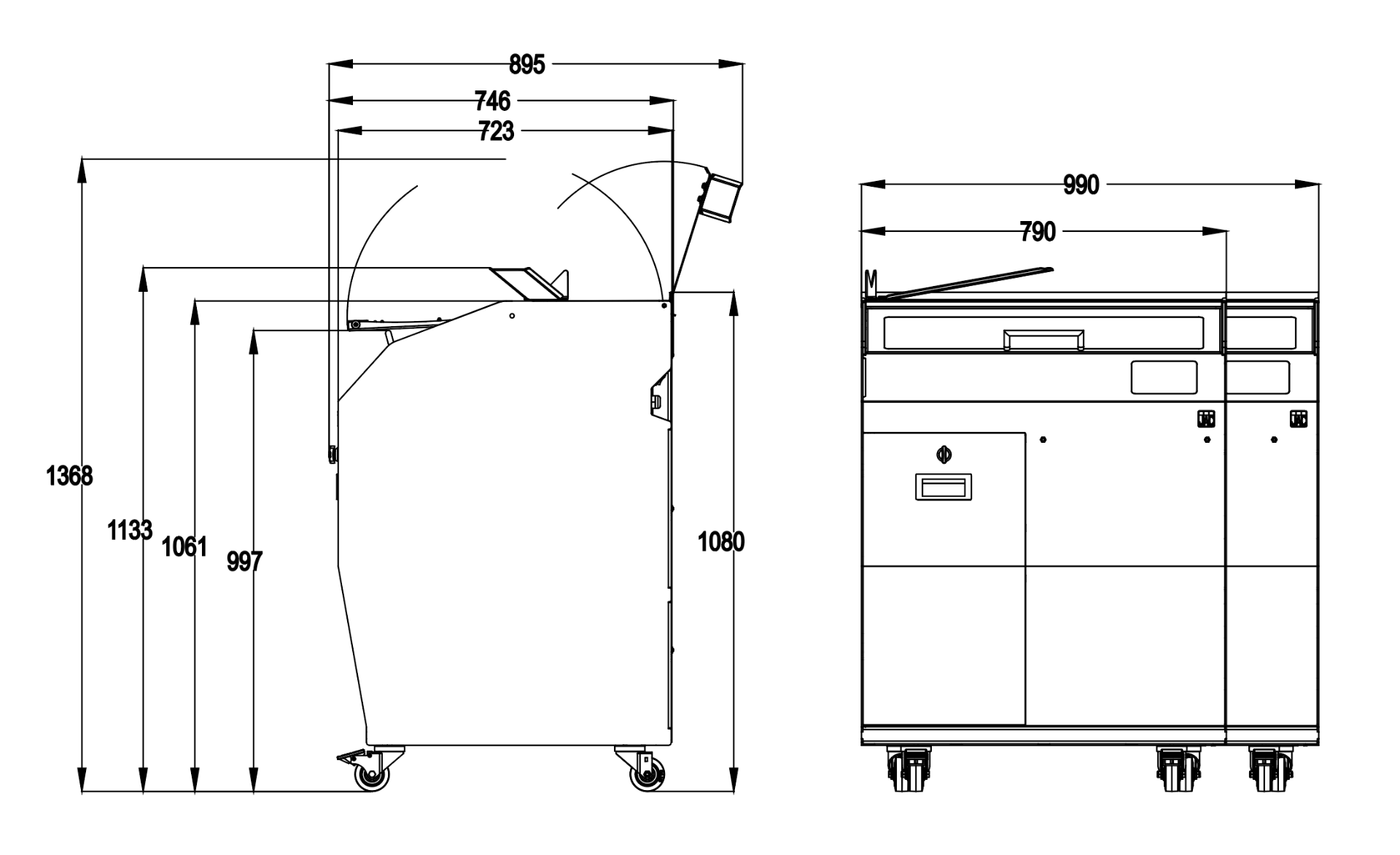

Size of entry channel (L x W x H) in inches |

14,9’’ x 13,4’’ x 6,3’’ |

|

Slice thickness in mm |

Can be set from 5 to 25mm |

|

Power supply |

208-230v/1ph |

|

Motor power in kW |

0.75 |

|

Net weight in lbs |

507 |

|

Blade type and dimensions in inches |

16,5’’ diameter, Teflon-coated |

|

Automatic claw |

• |

|

10 cm Front bagging stand

|

• |

|

Bag holder |

• |

|

Led lights |

• |

|

Dual Pro & Self touch screen controls |

• |

|

Upper cover |

• |

|

Cleaning position |

• |

SHARE