We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

The GDS divider is equipped with an open hopper. It is capable of a sustained production rate and highly consistent weights. Equipped as standard with a pre-rounding tile, an integral flour dispenser and optional weight setting, it is the perfect addition to an automated line.

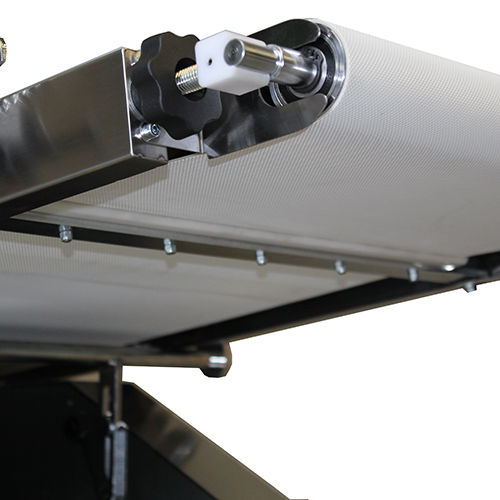

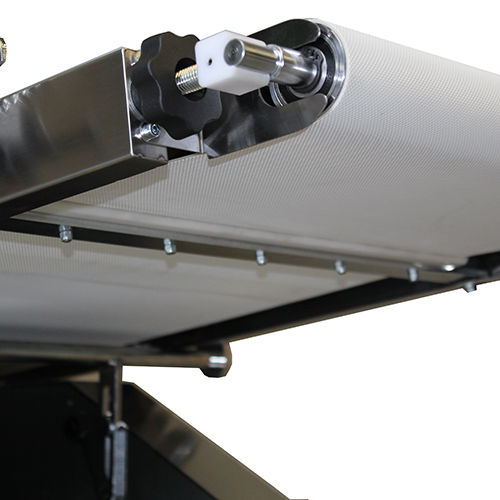

The belt is kept clean throughout use.

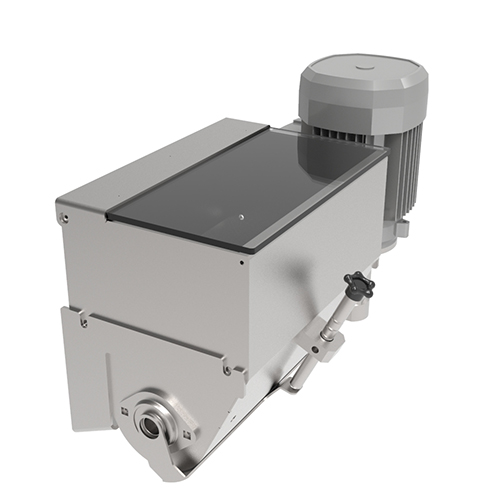

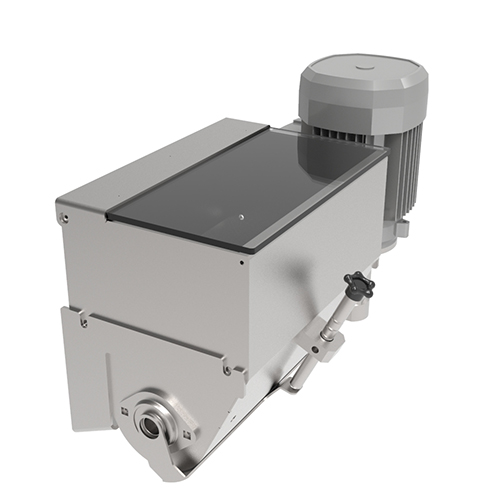

Reduces oil consumption. Fitted with a filter and a low level alert.

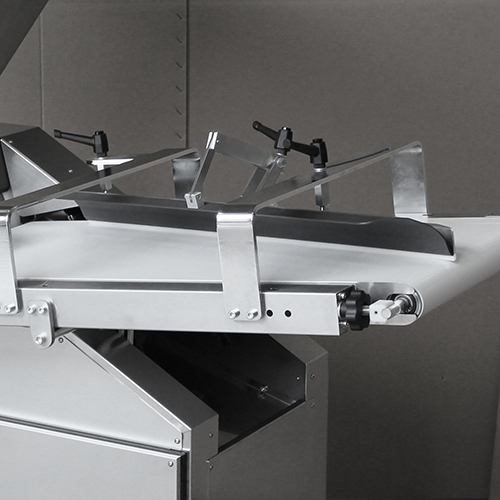

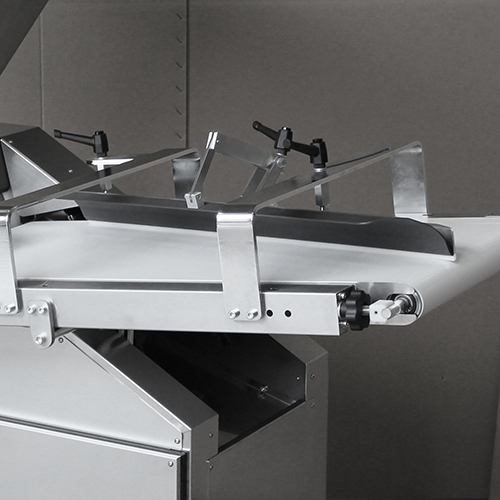

For pre-rounding dough pieces with different weights.

Prevents the dough pieces from sticking to the belt.

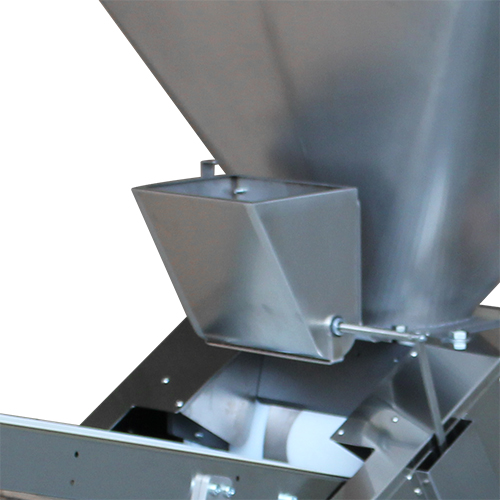

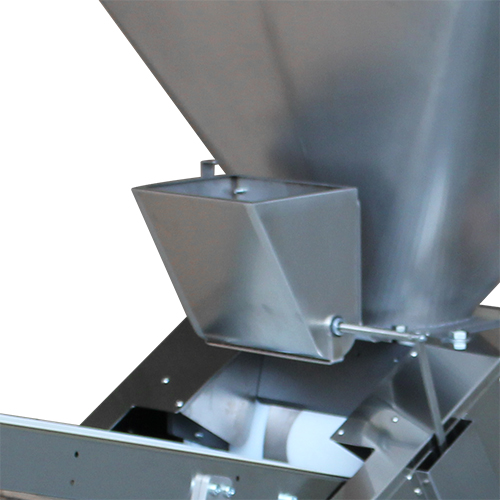

JAC has developed a brand new, more efficient integrated flour dispenser with a more regulated flow. It now equips the GD and GDS series.

The belt is kept clean throughout use.

Reduces oil consumption. Fitted with a filter and a low level alert.

For pre-rounding dough pieces with different weights.

Prevents the dough pieces from sticking to the belt.

JAC has developed a brand new, more efficient integrated flour dispenser with a more regulated flow. It now equips the GD and GDS series.

|

Adjustable speed in pieces per hour |

960 - 2000 |

|

Teflon-coated hopper, capacity in kg |

120 |

|

Programmable counter, countdown counter |

• |

|

Stainless steel drum |

• |

|

Triple-seal Rilsan piston |

• |

|

Stainless steel exterior |

• |

|

Outfeed belt width in mm |

500 |

|

3-litre flour dispenser |

• |

|

Outfeed belt scraper |

• |

|

Adjustable pre-rounding tile |

• |

|

Oil recycling system |

• |

|

Motor power in kW |

2.2 |

|

Power supply |

400V three-phase |

|

Net weight in kg |

575 |

|

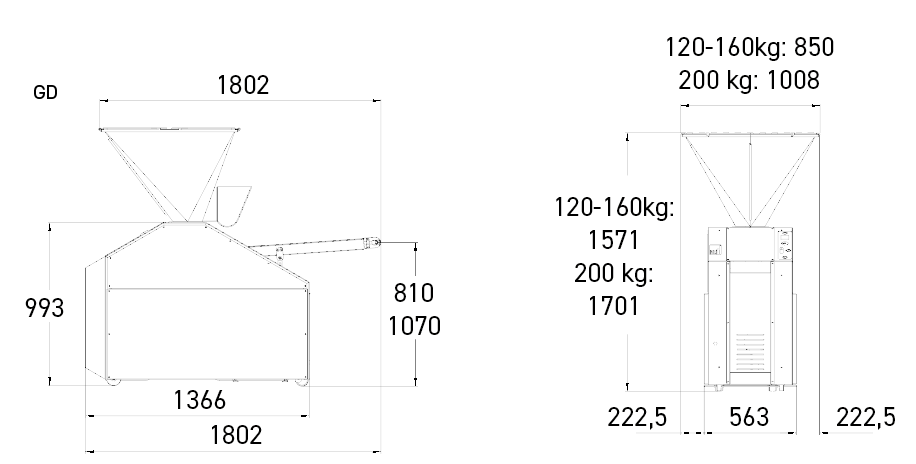

Outfeed belt length in mm

|

1.060 |

SHARE