We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

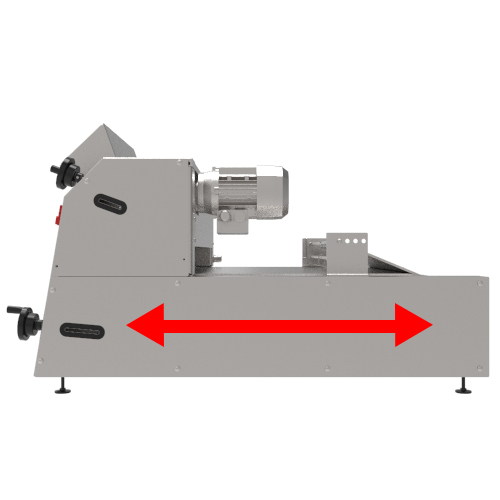

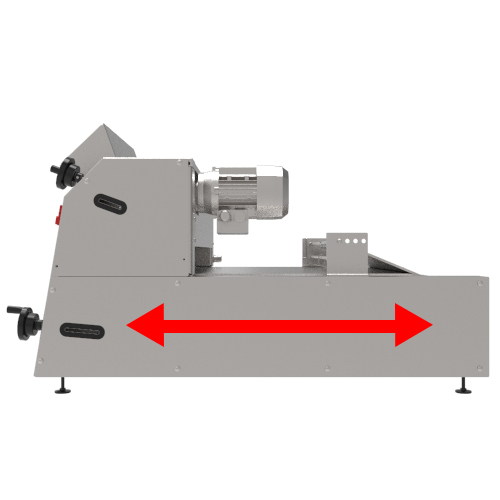

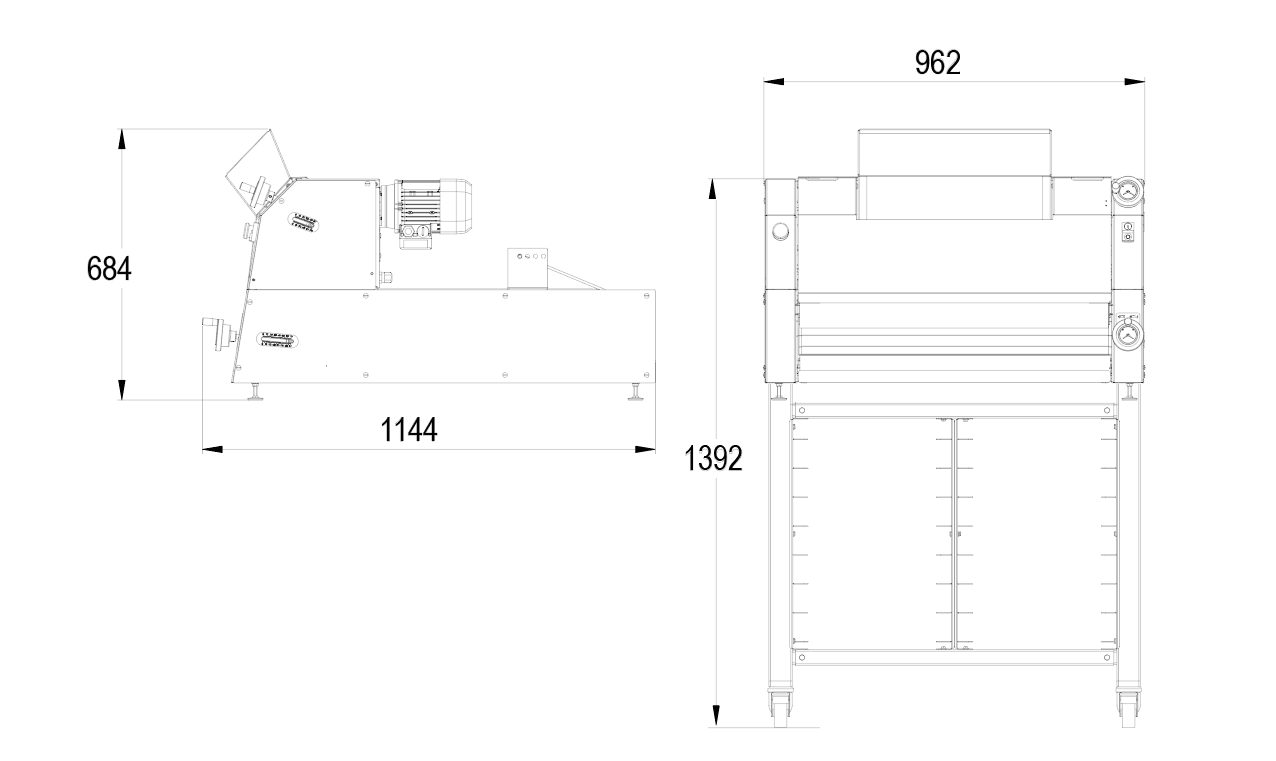

There is a wide range of JAC moulders and it enables everyone to find a moulder to suit their product range. The HF is the horizontal moulder in the range. Horizontal moulding allows working with minimal pressure on the dough since there is no need to counteract gravity when moving the dough piece on. The disadvantage of the HF is its overall size, which is larger than that of a vertical moulder, its advantage, besides being kind to the dough, is its more sustained production rate. Equipped with two sheeting rollers it, will be capable of moulding up to 1,800 pieces an hour. It can be installed on a base, on a proofer or on your worktop.

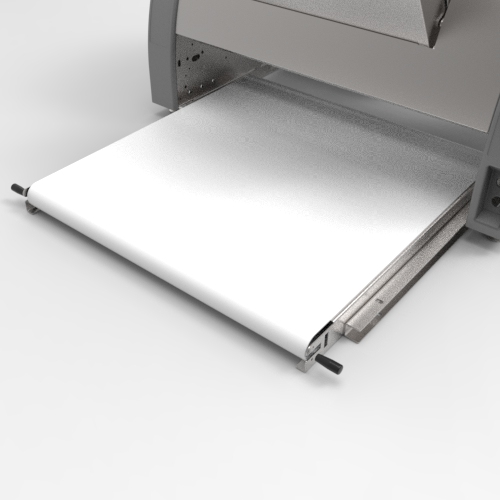

Two food-grade polyethylene rollers

Horizontal moulding to take maximum care of the dough

Thanks to the chain mail

Ergonomic, accurate indicators

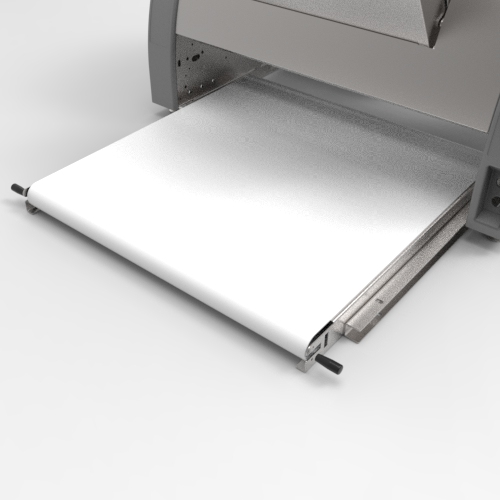

Facilitates unloading.

Two food-grade polyethylene rollers

Horizontal moulding to take maximum care of the dough

Thanks to the chain mail

Ergonomic, accurate indicators

Facilitates unloading.

|

Min/max weight of dough pieces in grams |

50 / 1300 |

|

Two food-grade PETP rolling rollers |

• |

|

Maximum speed in pieces per hour |

1800 |

|

Motor power in kW |

0.37 |

|

Net weight in kg |

180 |

SHARE