We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

The Paniform is the ultimate and fully automatic version in the range of JAC dividers. The perfect combination of an in-tank divider and grid divider, the Paniform is suitable for all types of dough, it will enable you to divide up to 19 kg in tank or 5 kg via a grid. It is equipped with a pressure plate and a grid holder to benefit from the very wide range of over 100 grids, from which you are bound to find THE right mould for your product.

JAC has made ambitious technical choices: reinforced piston, cast aluminium floats with EASY CLEAN treatment, Click&Cut, Start and Stop system, sharpened stainless-steel knives, square stainless-steel tank, flour recovery system, tamping pressure and time setting facility, Stress Control, Easyflour flour dispenser as standard and Fullmatic automatic tamping and cutting cycle. These advantages make it THE benchmark divider-moulder on the bakery market.

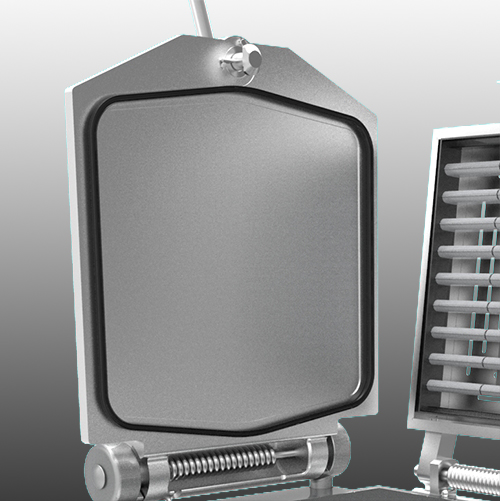

This extremely tough treatment is impregnated into the material; its exceptional non-stick qualities improve over time.

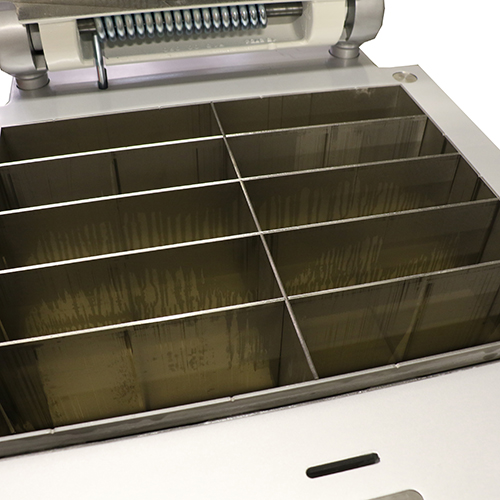

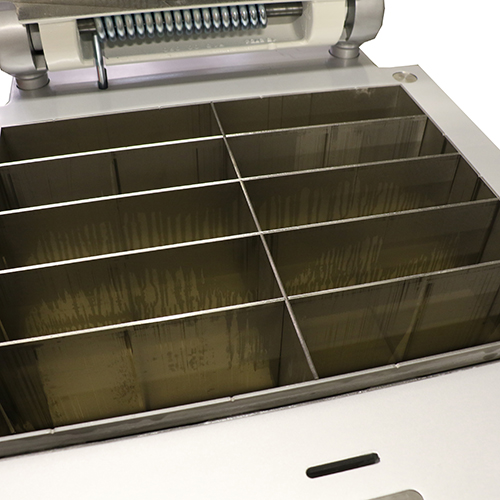

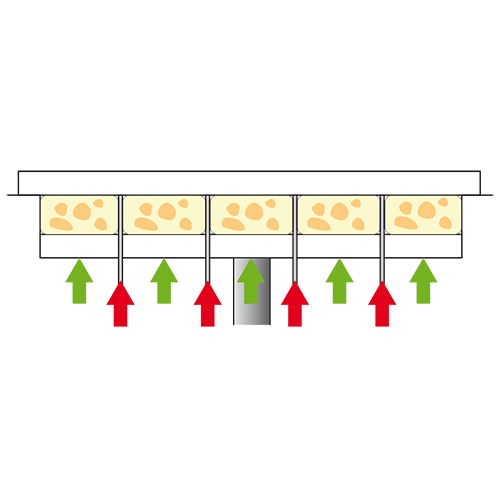

10 / 20 divisions Allows working in 10 divisions (230mm x 75mm) or 20 divisions (115mm x 75mm)

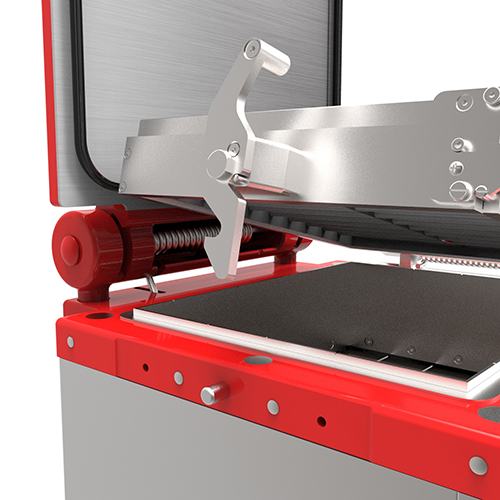

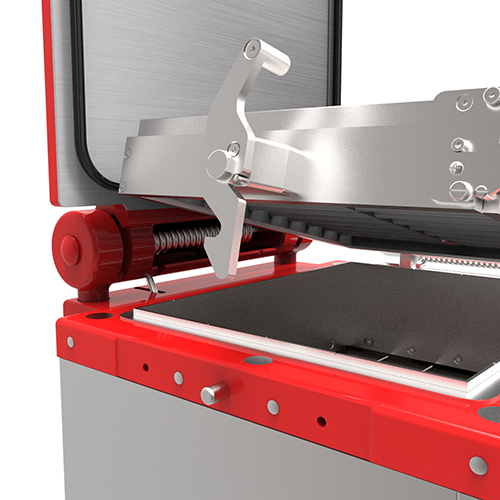

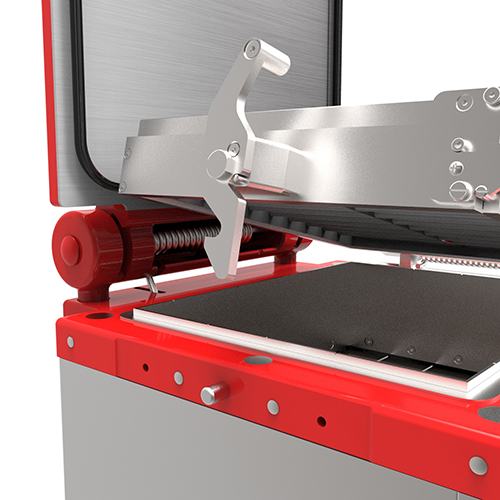

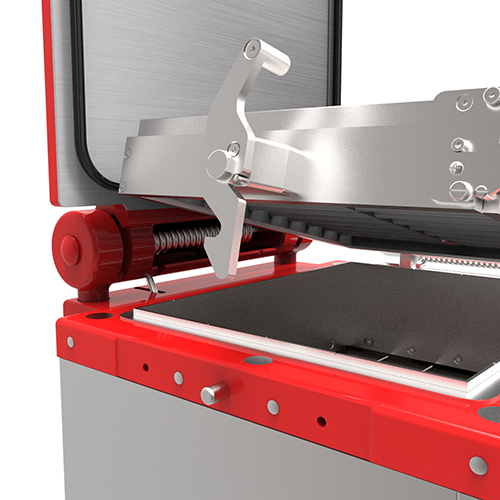

Automatic grid holder locking system On closing, the grid holder locks automatically and starts the automatic dividing cycle.

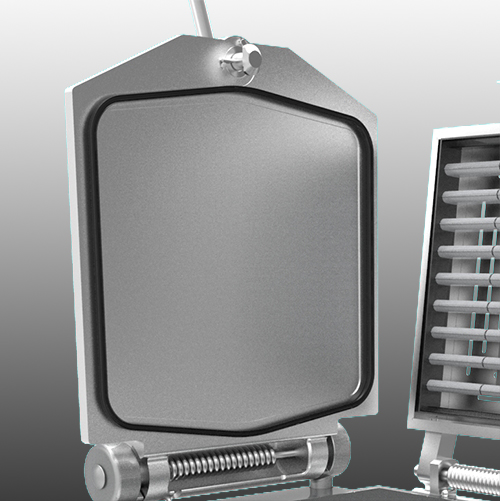

Quick grid changing system (JAC patent)

Prevents flour dispersal.

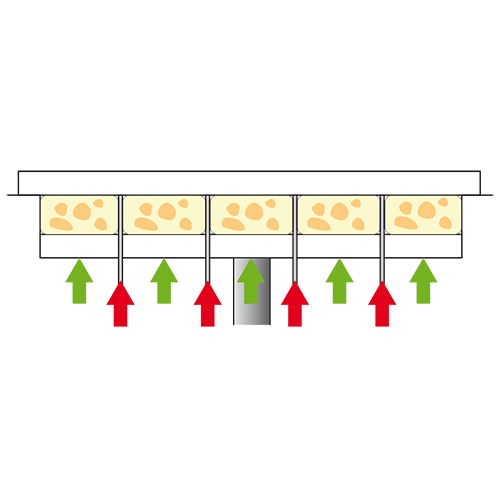

For better degassing management. Differentiated cutting pressure and tamping pressure.

Easyflour patented built-in flour dispenser Flours the tank in a single linear movement

Stress Control system, differentiated tamping and cutting pressure. Managing tamping pressure and time Achieves optimum tamping without degassing the dough. Automatic tamping and cutting cycle Automatic raising of dough pieces and tank knife cleaning mode

Automatic grid holder locking system On closing, the grid holder locks automatically and starts the automatic dividing cycle.

So as not to stress the dough

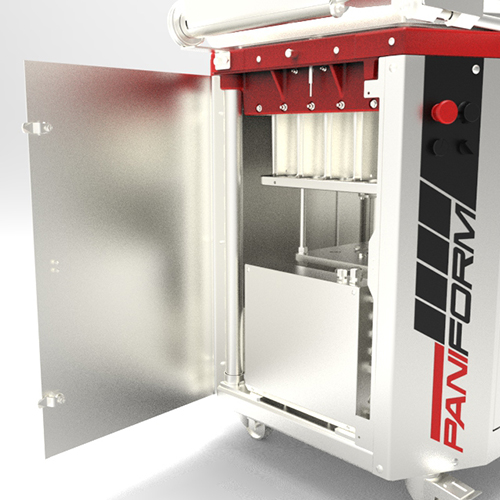

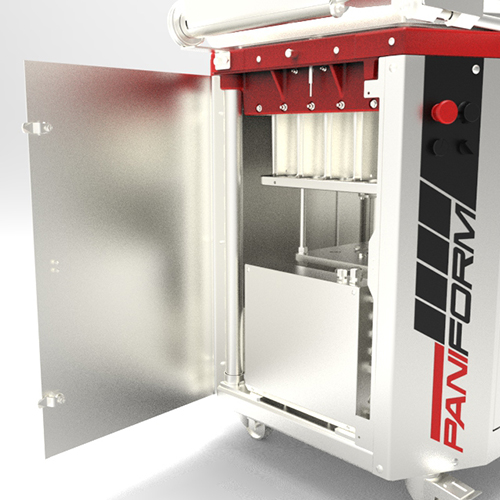

Allows easy access to the interior of the machine without tools.

This extremely tough treatment is impregnated into the material; its exceptional non-stick qualities improve over time.

10 / 20 divisions Allows working in 10 divisions (230mm x 75mm) or 20 divisions (115mm x 75mm)

Automatic grid holder locking system On closing, the grid holder locks automatically and starts the automatic dividing cycle.

Quick grid changing system (JAC patent)

Prevents flour dispersal.

For better degassing management. Differentiated cutting pressure and tamping pressure.

Easyflour patented built-in flour dispenser Flours the tank in a single linear movement

Stress Control system, differentiated tamping and cutting pressure. Managing tamping pressure and time Achieves optimum tamping without degassing the dough. Automatic tamping and cutting cycle Automatic raising of dough pieces and tank knife cleaning mode

Automatic grid holder locking system On closing, the grid holder locks automatically and starts the automatic dividing cycle.

So as not to stress the dough

Allows easy access to the interior of the machine without tools.

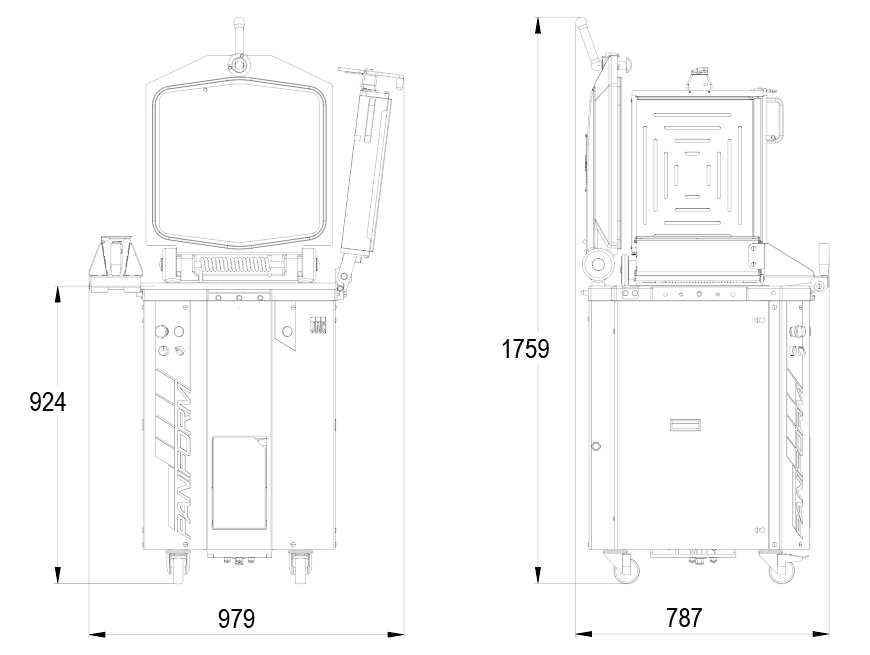

|

Tank dimensions (LxWxH) in mm |

460 x 387 x 125 |

|

Dimensions of pressing plates (L x W) in mm |

115 x 75 |

|

Min/max weight of dough pieces in grams |

150/950 |

|

Tank capacity in kg |

19 |

|

Min / max weight in grams in 10-division position |

300/1,900 |

|

Motor power rating in kW |

1.5 |

|

Net weight in kg (including frame) |

285 |

|

Easyflour |

• |

|

Fullmatic |

• |

|

Easylock |

• |

|

Click&cut |

• |

|

Easyclean |

• |

|

Managing tamping pressure and time |

• |

|

Automatic dough decompression cycle |

• |

|

Automatic knife retraction |

• |

|

Tank knife cleaning mode |

• |

|

Flour anti-splatter and recovery system |

• |

|

Stainless-steel bodywork, tank and knives |

• |

SHARE