We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

The Pro+ automated production line is perfectly compatible with the rest of the JAC range, dividers and moulders are the perfect addition to the Pro+ to make it into a veritable distillation of technology which will automate and stabilise your production. Maximum hygiene, product stability, high production rates: these are the stand-out features of the Pro+.

Germicidal UV lamp with protection and air extractor Sterilises the proofing area and extracts moisture. Hygiene Smooth inside walls Stainless steel exterior covers Flour recovery bins

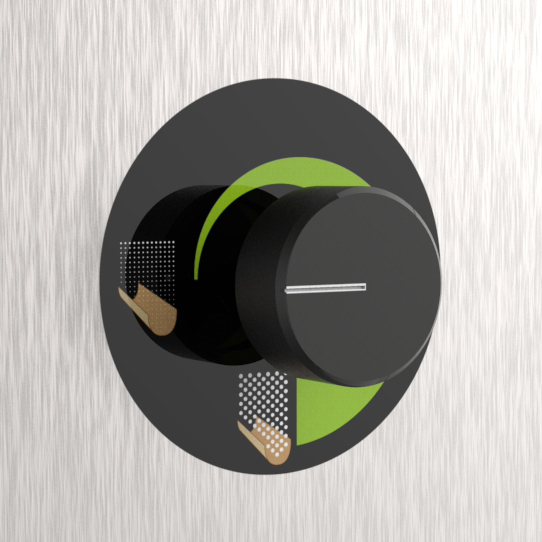

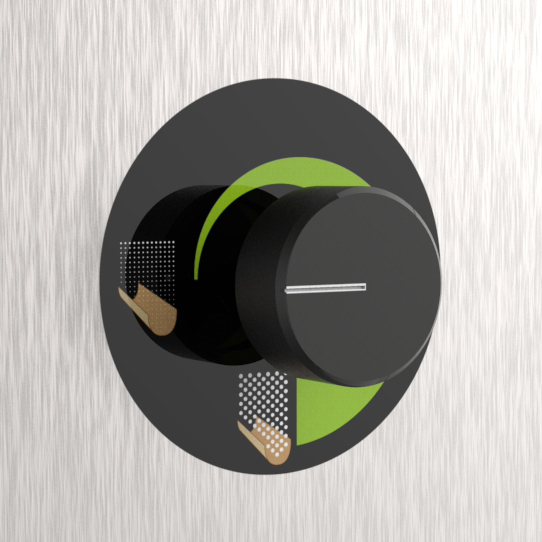

For simple, centralised control.

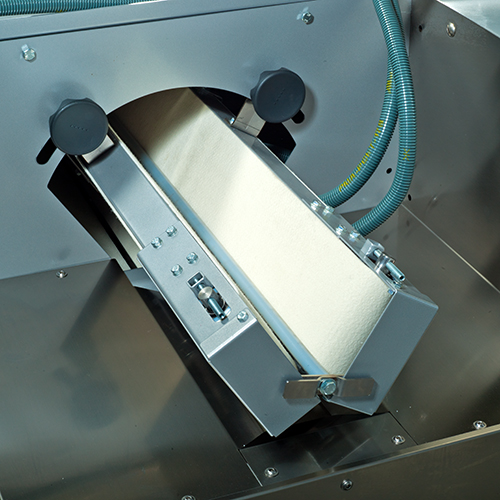

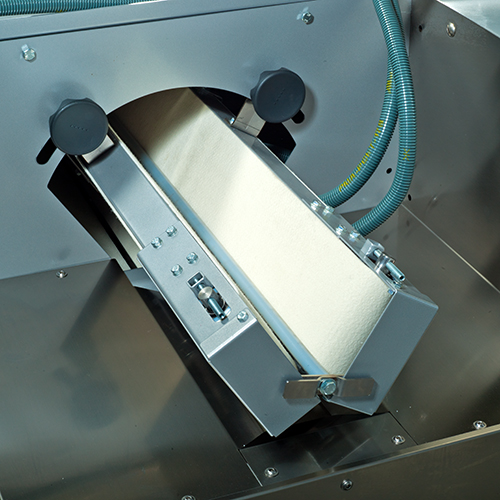

Adjustable inclination of the belt for an accurate setting.

Can be swivelled 180° for a configuration with an external moulder.

Ergonomic: Easy filling of the tank from the outside as well as quick visibility of the filling level. Hygienic: All stainless steel construction with easy dismantling for cleaning. Easy to use: A variable speed drive allows you to simply manage the flouring intensity, or disengage it if necessary.

Germicidal UV lamp with protection and air extractor Sterilises the proofing area and extracts moisture. Hygiene Smooth inside walls Stainless steel exterior covers Flour recovery bins

For simple, centralised control.

Adjustable inclination of the belt for an accurate setting.

Can be swivelled 180° for a configuration with an external moulder.

Ergonomic: Easy filling of the tank from the outside as well as quick visibility of the filling level. Hygienic: All stainless steel construction with easy dismantling for cleaning. Easy to use: A variable speed drive allows you to simply manage the flouring intensity, or disengage it if necessary.

|

Germicidal lamp |

• |

|

Retractable evacuation belt |

• |

|

Unloading belt |

• |

|

Flour dispenser |

• |

|

Water-repellent troughs (Arconet®) |

• |

|

Adjustable rounder |

• |

|

Air extractor |

• |

|

Motor power in kW |

0.72 |

|

Net weight in kg |

655 |

|

Standard troughs: 600g max dough pieces |

|

|

Features |

|

|

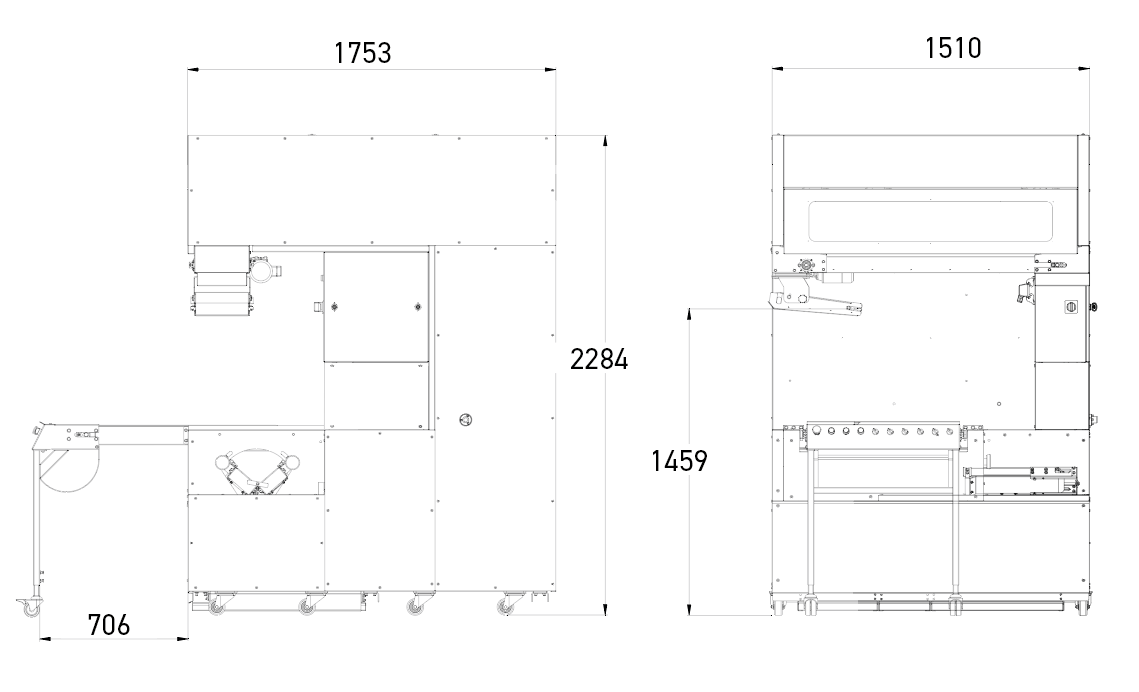

Length x width x depth in cm |

230 x 150 x 175 |

|

Length of troughs in cm |

122 |

|

Width of troughs in cm |

13 |

|

Number of usable troughs |

59 |

|

Usable capacity with 350 g dough pieces |

295 |

|

Number of dough pieces per trough |

5 |

|

Usable capacity with 550 g dough pieces |

236 |

|

Number of dough pieces per trough |

4 |

|

Standard troughs: 600g max dough pieces |

Proofing time in min |

|||

|

Number of dough pieces |

Number per trough |

960 per hour |

1200 per hour |

1400 per hour |

|

236 |

4 |

15 |

12 |

10 |

|

295 |

5 |

18 |

15 |

13 |

|

413 |

7 |

26 |

21 |

18 |

|

Wide troughs: 950g max dough pieces |

|

|

Features |

|

|

Length x width x depth in cm |

230 x 150 x 175 |

|

Length of troughs in cm |

122 |

|

Width of troughs in cm |

16 |

|

Number of usable troughs |

47 |

|

Usable capacity with 350 g dough pieces |

235 |

|

Number of dough pieces per trough |

5 |

|

Usable capacity with 550 g dough pieces |

Reset |

|

Number of dough pieces per trough |

4 |

|

Usable capacity with 950 g dough pieces |

141 |

|

Number of dough pieces per trough |

3 |

|

Wide troughs: 950g max dough pieces |

Proofing time in min |

|||

|

Number of dough pieces |

Number per trough |

960 per hour |

1200 per hour |

1400 per hour |

|

141 |

3 |

8 |

7 |

6 |

|

188 |

4 |

12 |

9 |

8 |

|

235 |

5 |

15 |

12 |

10 |

|

329 |

7 |

21 |

17 |

14 |

SHARE