We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Consistent cutting speed and no adjustment needed make the Swift, a multi-format batch slicer, the ideal slicer for bakeries. Place your batch of loaves of all sizes on the infeed belt of the machine and the slicer will slice them one after another with ease.

Intelligent Slicing Control (JAC patent) is an automatic pressure and slicing speed control system. It adapts the cutting action according to the consistency of the bread. No manual setting needed. The ISC® with extended mode selector provides two extra automatic modes, to adapt to extreme cutting condition of very fresh breads or the need for particularly fast cutting rate.

Accessible by tilting the front, cylinder-assisted door. 18 litre capacity.

Saves packaging time.

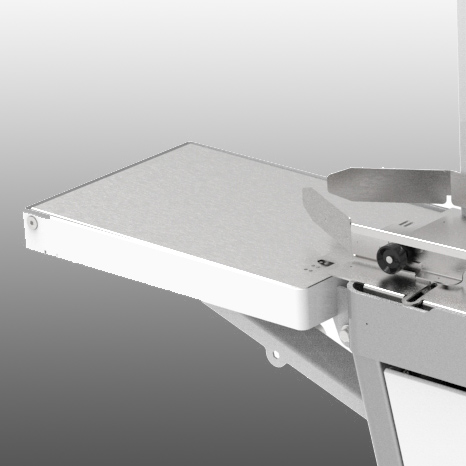

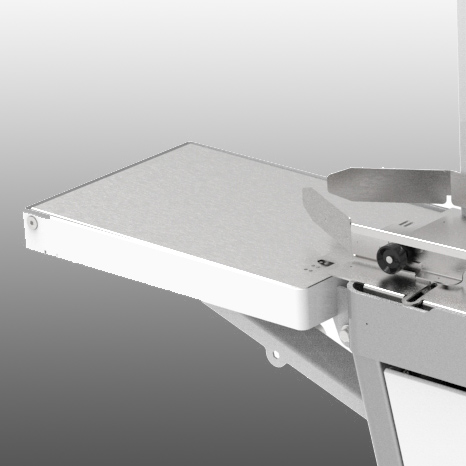

The loading area consists of rollers on ball bearings to automatically direct loaves to the loaf changeover area. Given that it is located facing the operator, this simplifies the handling of loaves considerably. It is not necessary to make adjustments for different loaf formats, as the slicer adapts, saving you time and improving ergonomics.

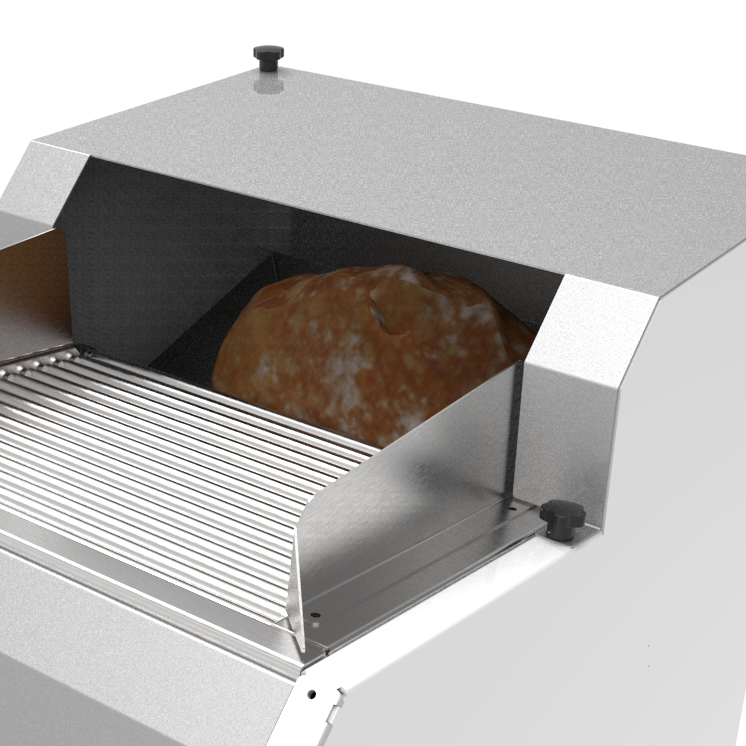

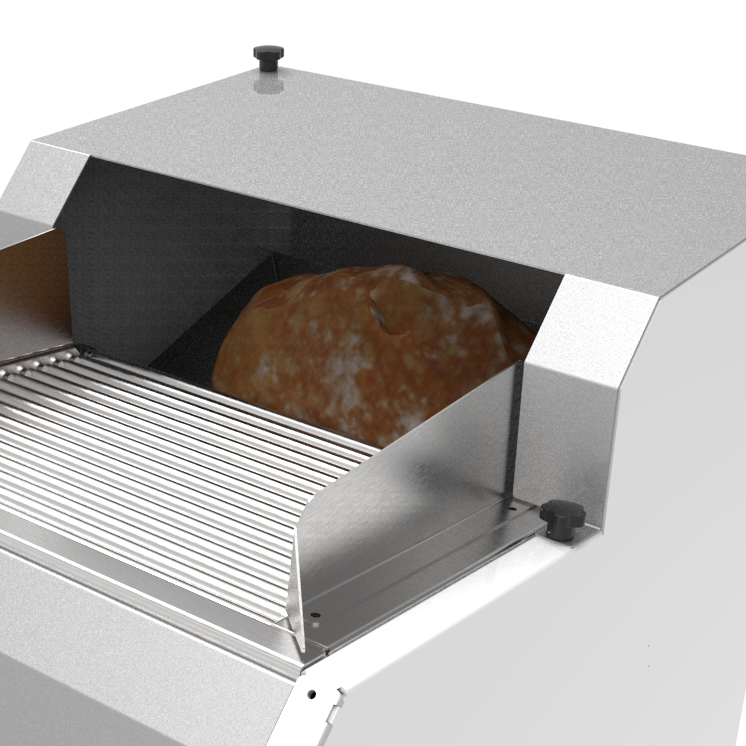

The tilting zone makes the transition between the loading table and the cutting table. With each passage of a loaf, the tilting zone rotates to deposit the loaf on the cutting area. This area is secured by cells that prevent it from functioning if the operator puts his hand or anything else in it. A mechanical barrier blocks the passage of other loaves during tilting.

The delivery area is located at the correct height to facilitate the handling of loaves sliced. As it is provided with holes, any crumbs fall into the recovery tray.

100% BPA-free satin paint (Bisphenol A): safer for you, gentler on the planet. Its low-temperature curing process significantly reduces energy consumption. Available in three solid colours: white, black or grey.

Intelligent Slicing Control (JAC patent) is an automatic pressure and slicing speed control system. It adapts the cutting action according to the consistency of the bread. No manual setting needed. The ISC® with extended mode selector provides two extra automatic modes, to adapt to extreme cutting condition of very fresh breads or the need for particularly fast cutting rate.

Accessible by tilting the front, cylinder-assisted door. 18 litre capacity.

Saves packaging time.

The loading area consists of rollers on ball bearings to automatically direct loaves to the loaf changeover area. Given that it is located facing the operator, this simplifies the handling of loaves considerably. It is not necessary to make adjustments for different loaf formats, as the slicer adapts, saving you time and improving ergonomics.

The tilting zone makes the transition between the loading table and the cutting table. With each passage of a loaf, the tilting zone rotates to deposit the loaf on the cutting area. This area is secured by cells that prevent it from functioning if the operator puts his hand or anything else in it. A mechanical barrier blocks the passage of other loaves during tilting.

The delivery area is located at the correct height to facilitate the handling of loaves sliced. As it is provided with holes, any crumbs fall into the recovery tray.

100% BPA-free satin paint (Bisphenol A): safer for you, gentler on the planet. Its low-temperature curing process significantly reduces energy consumption. Available in three solid colours: white, black or grey.

|

Max. loaf dimensions in cm (L x W x H) |

44 x 31 x 16 |

|

Motor power in kW |

0.49 |

|

Net weight (in kg) |

165 |

|

Blade type and dimensions in mm |

13 x 0.5 steel |

|

ISC extended mode selector |

• |

SHARE