We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Any passionate baker knows the value of baking based on liquid sourdough.

Sourdough is a liquid dough with equal parts of water and flour subjected to natural fermentation, the function of which is to produce acids that are beneficial for kneading the dough. These acids also improve the appearance and taste of the product. They allow longer storage and significantly improve nutritional qualities.

Above all, it is a way to personalize your production and retain your customers with a taste that you can work in your own way and that your customers will not find in your competitors.

In theory, mastering the production of liquid sourdough can raise questions. In reality, there is nothing simpler and more rewarding, as long as you have the ideal machine.

At JAC, our international activity has allowed us to face many challenges because the liquid sourdough used in Lyon is not that of Moscow, Barcelona, New York, Berlin or Brussels.

But a versatile machine and a well-mastered process make it possible to efficiently meet all these needs.

This automatic agitation management system based on fermentation activities makes Tradilevain smarter. It triggers its agitation cycles only when necessary by analyzing the level of fermentation. Less agitation, the leaven is of better quality. No more complicated cycle programming.

The Tradilevain will adjust the stirring speed according to the volume of sourdough present in order to stir it without damaging it.

In addition to being equipped with an anti-overflow system, the Tradilevain is equipped with a low level warning system that can be configured according to your production: the Minicare. This way you can be sure that you always have a minimum of intact mother leaven at the bottom of the tank.

JAC has developed a gentle heat system that allows the temperature to be maintained during long fermentation cycles or to adjust an imprecise water temperature by a few degrees during cooling.

JAC has developed a gentle heat system that allows the temperature to be maintained during long fermentation cycles or to adjust an imprecise water temperature by a few degrees during cooling.

An all stainless steel machine for ease of cleaning and without deterioration over time.

A large touch screen (7 inches), very intuitive, set back from the bodywork and in an oblique position for perfectly ergonomic use. 2 factory recipes and 6 customizable recipes. A built-in calculator to help you keep track of the amount of leaven left in the tank.

Allows an oxygen supply when necessary.

The monobloc stainless steel tank tower is perfectly sealed and hygienic. Its rim prevents impurities from falling into the tank.

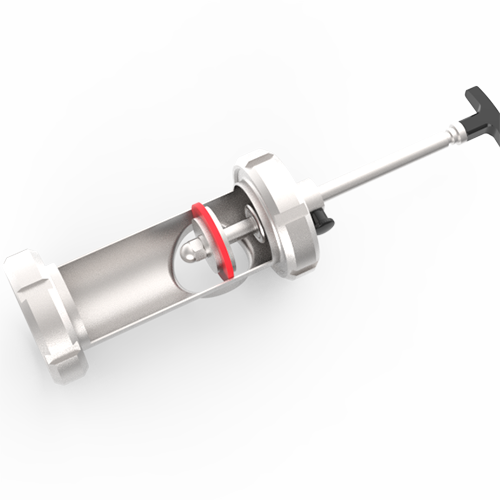

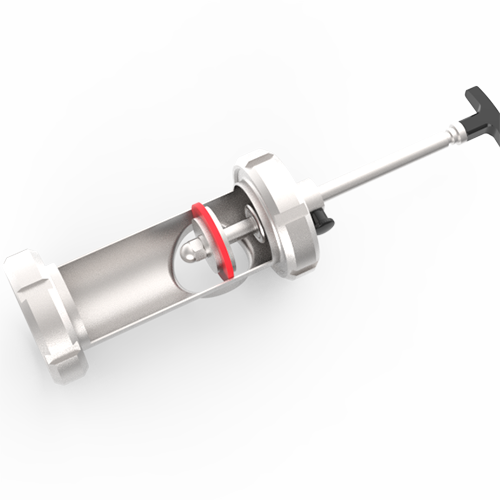

The airtight tank seal is placed around the lid. It can be dismantled in a few seconds for easy cleaning.

A mixing system by submerged blades that requires little maintenance and avoids the drift of the sourdough (the sourdough which dries on the mixing arms of standard sourdough machines ends up developing bacteria which fall into the tank and destabilize the bacteriological balance) . The profile of the mixing blades has been reworked to offer a 75% more powerful mixing.

Easy to dismantle for quick cleaning.

Recessed handles are integrated into the stainless steel side walls for easy movement of the machine.n

The cold group makes it possible to control the temperature of the leaven during the various production cycles.

2 recipes stored in the factory and 6 customizable recipes, 3 in the classic cycle and 3 in the Automix cycle.

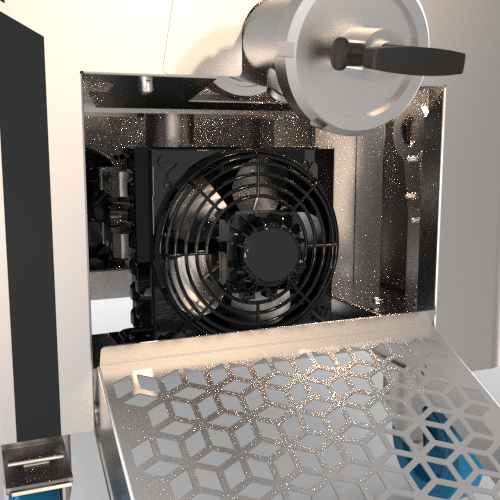

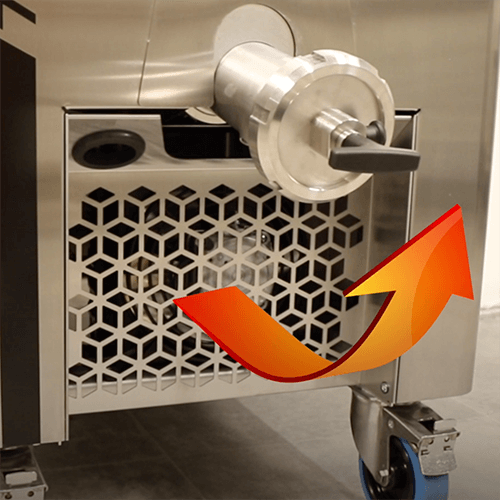

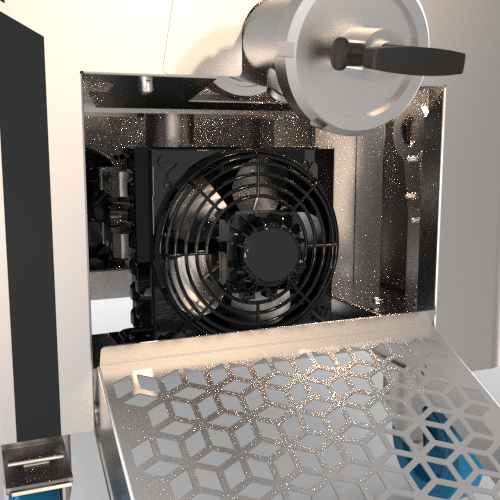

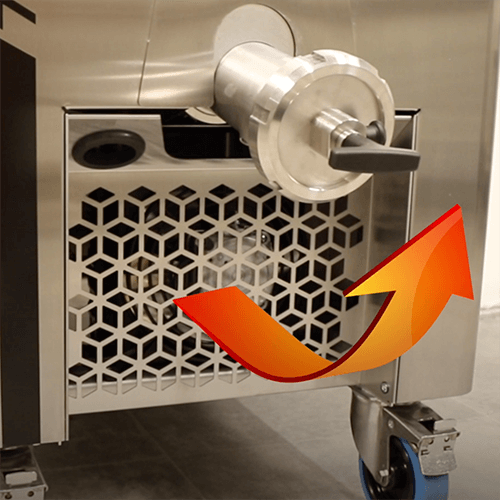

A hot air vent from the cooling unit on the front to optimize the cooling performance of the machine and facilitate cleaning (without tools) of the cooler.

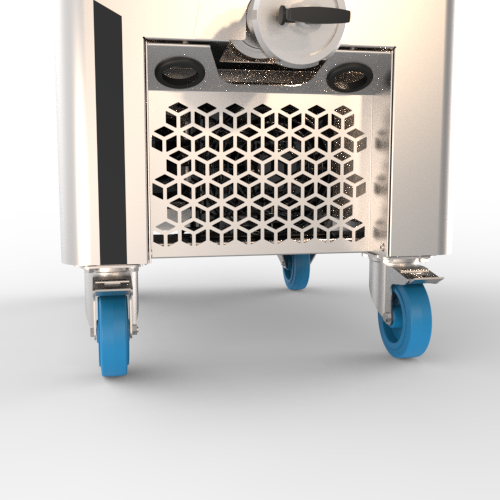

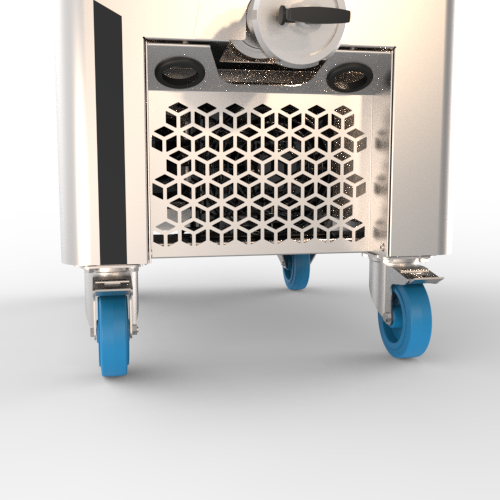

Large locking casters to facilitate movement and ensure good stability.

Thanks to the new profiles of the propeller and the tank, the mixing of a complete tank - no matter the size of your Tradilevain - is done in 1 minute and 30 seconds. A significant time saver when most fermenters can take up to 20 minutes. During a refresh, you can worry-free load your flour in one go. The propeller will have no trouble making the mixture homogeneous.

This automatic agitation management system based on fermentation activities makes Tradilevain smarter. It triggers its agitation cycles only when necessary by analyzing the level of fermentation. Less agitation, the leaven is of better quality. No more complicated cycle programming.

The Tradilevain will adjust the stirring speed according to the volume of sourdough present in order to stir it without damaging it.

In addition to being equipped with an anti-overflow system, the Tradilevain is equipped with a low level warning system that can be configured according to your production: the Minicare. This way you can be sure that you always have a minimum of intact mother leaven at the bottom of the tank.

JAC has developed a gentle heat system that allows the temperature to be maintained during long fermentation cycles or to adjust an imprecise water temperature by a few degrees during cooling.

JAC has developed a gentle heat system that allows the temperature to be maintained during long fermentation cycles or to adjust an imprecise water temperature by a few degrees during cooling.

An all stainless steel machine for ease of cleaning and without deterioration over time.

A large touch screen (7 inches), very intuitive, set back from the bodywork and in an oblique position for perfectly ergonomic use. 2 factory recipes and 6 customizable recipes. A built-in calculator to help you keep track of the amount of leaven left in the tank.

Allows an oxygen supply when necessary.

The monobloc stainless steel tank tower is perfectly sealed and hygienic. Its rim prevents impurities from falling into the tank.

The airtight tank seal is placed around the lid. It can be dismantled in a few seconds for easy cleaning.

A mixing system by submerged blades that requires little maintenance and avoids the drift of the sourdough (the sourdough which dries on the mixing arms of standard sourdough machines ends up developing bacteria which fall into the tank and destabilize the bacteriological balance) . The profile of the mixing blades has been reworked to offer a 75% more powerful mixing.

Easy to dismantle for quick cleaning.

Recessed handles are integrated into the stainless steel side walls for easy movement of the machine.n

The cold group makes it possible to control the temperature of the leaven during the various production cycles.

2 recipes stored in the factory and 6 customizable recipes, 3 in the classic cycle and 3 in the Automix cycle.

A hot air vent from the cooling unit on the front to optimize the cooling performance of the machine and facilitate cleaning (without tools) of the cooler.

Large locking casters to facilitate movement and ensure good stability.

Thanks to the new profiles of the propeller and the tank, the mixing of a complete tank - no matter the size of your Tradilevain - is done in 1 minute and 30 seconds. A significant time saver when most fermenters can take up to 20 minutes. During a refresh, you can worry-free load your flour in one go. The propeller will have no trouble making the mixture homogeneous.

|

Automix |

• |

|

Variospeed |

• |

|

Thermasoft |

• |

|

Minicare |

• |

|

Touch screen |

• |

|

Motor power (kW) |

4 |

|

Heating power in (kW) |

0,45 |

|

50Hz chiller power (kW) |

0,9 |

|

220v - 50Hz-60Hz (A) |

14,5 |

|

380v - 50Hz-60Hz (A) |

10 |

|

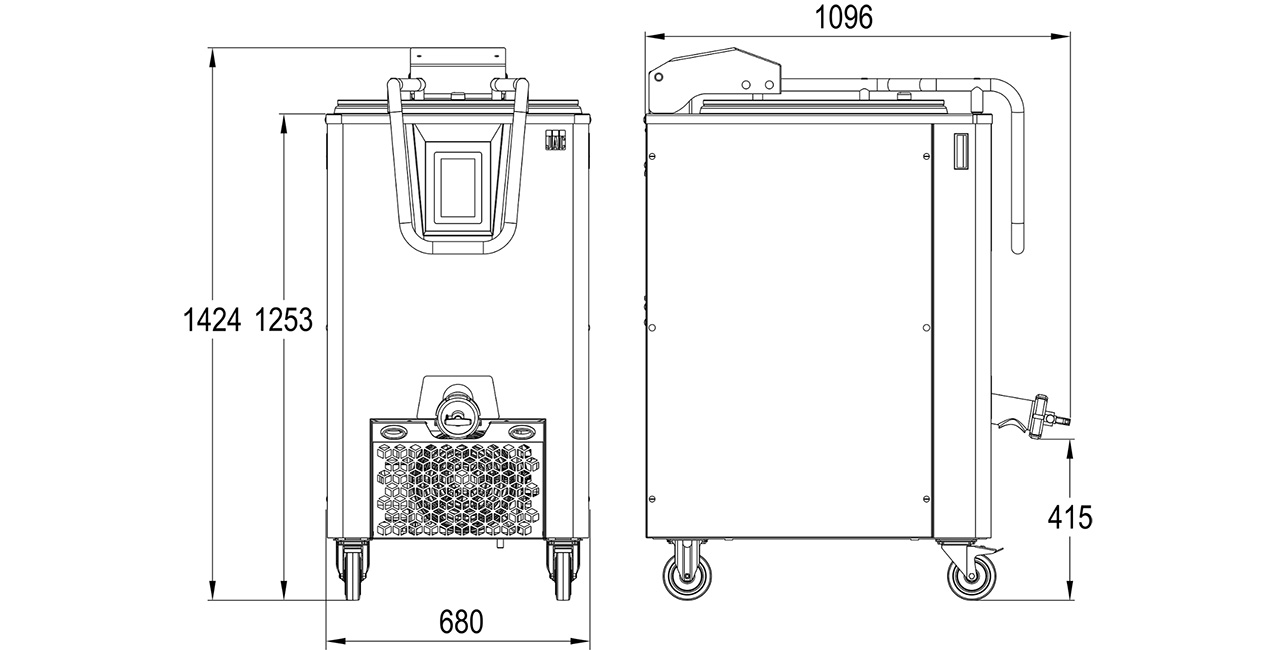

Loading height (cm) |

125 |

|

Tank volume in l |

220 |

|

Maximum total capacity (l) |

140 |

|

Maximum useful capacity (l) |

110 |

|

Minimum total capacity (l) |

70 |

|

Minimum useful capacity (l) |

55 |

SHARE